A modern apprenticeship in heritage science

Behind the Scenes, Science, Skills | Written by: Guest | Wednesday 5 March 2025

From historic site surveys to innovative material analysis, our laboratory assistant Jasper shares her pathway into heritage science.

Jasper Croser is in her third (and final) year of a Modern Apprenticeship. She is based within our Heritage Science Team, which applies conservation techniques to historic places and collections objects. As a laboratory assistant, she is involved in work at our material analysis facilities, as well as taking part in site surveys, events, training, and shadowing other teams.

Read on to discover how Jasper came to work in heritage science, find out what a heritage science apprenticeship is, the opportunities a modern apprenticeship brings, and what Jasper has learned from the experience.

The benefits of a modern apprenticeship in heritage science

I began my apprenticeship the summer after finishing high school. I could never have planned for it, it just so happened I was in the right place at the right time.

When applying, what drew me to the role was:

- immediately entering the workplace, while furthering my education

- gaining hands-on experience in industry

- the prospective crossover of my interests of science and history

- attaining college and workplace-based qualifications

- not committing to a degree

Modern apprenticeships are an alternative entry point into a career in science. In the area of heritage science this was the first of its kind. It created a huge learning opportunity for me and for my team as my technical skills and knowledge grew and I became established in my role.

How my apprenticeship is structured

To understand the components of my Modern Apprenticeship, I find it most helpful to break it down into four main areas:

HNC (Higher National Certificate) in Applied Sciences at Forth Valley College

I undertook this over 2 years on a 1 day a week programme. This covered a range of subjects and laboratory skills applicable to science in industry including chemistry, biology and statistics.

SVQ (Scottish Vocational Qualification) in Industrial Science

This is awarded through meeting criteria designed to fulfil an industry desired standard of competence and knowledge. Work is submitted to an assessor in the form of written reports, professional discussions and in-person observations.

Involvement in the HES Trainee and Craft Fellow Programme

This has given me access to a mentor who has supported me throughout my time at HES and has allowed me to form a network of relationships with other apprentices, trainees and craft fellows. With the group, there is also continued opportunity to attend various training and events together.

Work experience at Engine Shed Laboratory

I believe the most invaluable part of my apprenticeship is the experience I have gained through working with and being trained by a wonderful group of specialists. I have been continually met with the kindness and generosity of people sharing their time and expertise with me. Not just from within the Heritage Science team, but also wider in the organisation and from external partners.

Analysing materials in the lab

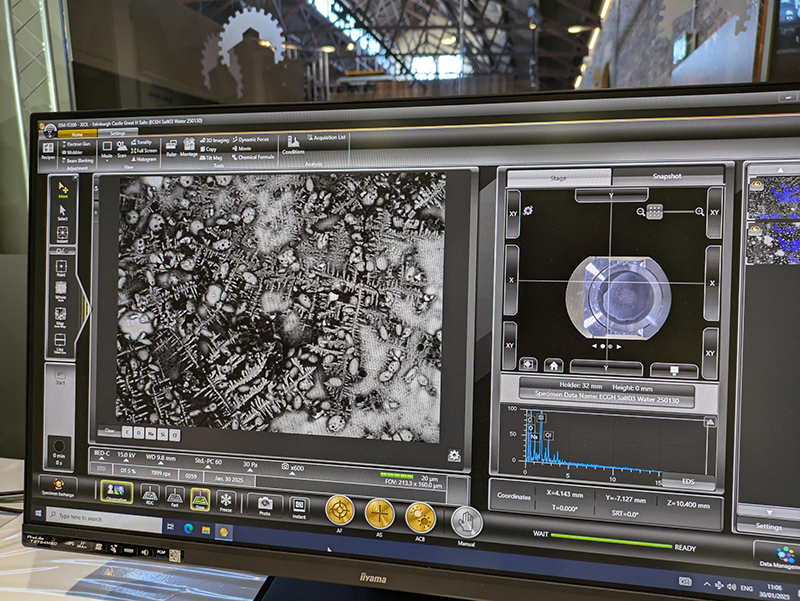

The typical samples I work with are stone or mortar samples from a HES site. The analysis methods may include techniques to extract clays and salts, wet chemistry and sample preparation for further analysis like X-Ray Diffraction (XRD) or Scanning Electron Microscopy (SEM).

Scanning Electron Microscope image of salt. This is one of the cutting edge technologies used at the Engine Shed.

I generally perform some but not all stages of the analysis of a sample as some areas require more specialist knowledge.

Sample preparation ahead of an XRD analysis.

The methods undertaken on each sample are decided on a case-by-case basis, they depend on the nature of the sample and the purpose of the analysis. For example, the purpose of the analysis may be to meet a request for material classification, diagnosing physical or chemical characteristics that are contributing to decay. Or it could be assessing the suitability of a proposed replacement or repair.

A sample can also present the option to be repurposed for use a in project. For example, I created guidance on how to achieve the best XRD results for the varying sizes of samples we encounter. The project used different types of sandstone and trialled the duration, intensity and solvent volume used in our grinding machine to determine the settings that yield the highest quality results for each given size of sample. This established a new standard for the preparation of all samples for XRD analysis by the team.

This information was used in a project investigating the decay mechanisms and characterisation of a stone from Linlithgow Palace, where they removed cores from different depths of the stone to map changes in its mineral composition. The drilling of the cores produced small amounts of powder that were retained for XRD analysis. The methodology that I developed ensured the samples were prepared in a consistent and reproductible way so that the results were comparable. The project highlighted how surface degradation affected the composition of the stone.

At the very least all samples are photographed, logged and stored in an archive as they may, at a future date, be required as a reference or further analysis.

An important part of my job is sample and inventory management. Ensuring sample logs contain up to date information and images and that all chemicals, consumables and equipment are listed, and stock levels are maintained within suitable limits.

I also supported the team in creating good practice for the health and safety compliance of the heritage science laboratory. I have developed a new dust protocol to limit exposure to silica dust during all lab procedures. As part of this, I have created COSHH (Control of Substances Hazardous to Health) assessments, updated the lab access procedure and I am currently undertaking a project reviewing and updating the lab’s risk assessments and standard operating procedures. The project will ensure that there is continuity in the information provided by all lab documentation and that this is compliant with the latest health and safety advice.

The use of different in-house and on-site equipment

I have had the opportunity to be trained on lots of different types of equipment and use them in a range of environments from the laboratory to stunning castles and muddy fields. Training usually covers theoretical principles, operation, software, data processing and interpretation of results.

Site surveys I have been involved in include the use of Microwave Moisture Sensing (MMS) equipment to gather data on the relative levels of moisture in walls.

Using an microwave moisture meter to measure the moisture of a window surround.

This type of survey collects data points in a grid pattern across a flat surface and has different sensor heads that can detect moisture to different depths. Once processed this data is used to create ‘moisture maps’ which indicate damp areas. This can be useful in investigating the extent of a damp issue in a building, the potential structural causes, and exacerbating factors of water ingress. It is also used to evaluate the effectiveness of repair works by repeating a survey sometime after the repair.

Another field technique I have had some experience in is Ground Penetrating Rader (GPR) technology. This is used to visualise subsurface structures. I used this at Edinburgh Castle to view an internal roof structure and at Inveresk Roman Fort with the Geophysics Team.

Learning about geology and building stone

My favourite moments from my apprenticeship have been when collaborating with others. While working on projects, on-site or on trips, I am getting the chance to visit some amazing places.

At the start of my apprenticeship in September 2022 my main task was to learn as much as possible about buildings in Scotland, the local materials, terminology, and conservation science. I did not expect to find stone of all things particularly interesting. I was lucky to have my manger, Dr Callum Graham, as an enthusiastic educator and I soon caught the very contagious geology nerd bug.

In October 2022 I attended a BGS (British Geological Survey) building stone geology workshop with other members of the Heritage Science Team. It was a really memorable and enjoyable day and provided me with a lot of contextual information. This was when I began to tie together the different concepts I was reading and hearing about and was able to gain a greater understanding of:

- the variety of stone that comes from Scotland

- how the characteristics of a building stone affect its performance in situ

- how stone can be identified and analysed through methods like Petrography

- and how a bad ‘stone match’ can result in a bad repair

I have been involved in the HES Stone Survey project by providing the lab support. Here, I was responsible for maintaining a tracker holding all the relevant information about the samples (nearing 400 in total), photographing them and organising them into appropriate storage in the lab.

Exploring the heritage industry on field trips

Every year craft fellows, trainees and apprentices go on a Continued Professional Development (CPD) trip. I am lucky to have gone twice, with a new group of people each time. Both years were an educational and fun experience, completely different, and a highlight of my time at HES. In March 2023 we went to different locations in Dundee and Angus and in May 2024 we went to Oban. The trip offered a fantastic opportunity to travel to and learn about different historical sites and the wider heritage industry. It also felt very meaningful to spend time with the craft fellows and trainees.

The annual CPD trip organised by the Trainee and Craft Fellow Programme.

Researching earth mortar

My final highlight has been getting the opportunity to work on different research projects.

Last year work was being undertaken at the Engine Shed to develop a methodology for the analysis of earth mortar. This was in response to the limited information available on standardised laboratory protocols for the material.

This is due to the fact there has been a larger focus on understanding lime mortar and the extent of the use of earth as a building material is still being determined.

The time allocated to the lab phase of the project was restricted by delays, so there was a tight deadline on the work. However, in this time there were lots of interesting developments made as the nature of the material presented new challenges. Different treatments like Loss-on-ignition (LOI) and acid digestion were explored. It was extremely rewarding that my knowledge of the techniques and equipment available at the Engine Shed was found useful.

During this time, we had many interesting and constructive brainstorming and troubleshooting conversations, which made this project stand out to me and makes this such a fond memory.

What’s next for me?

I have decided that I would like to further expand my knowledge, skills and opportunities by attending University.

As well as helping to make this opportunity possible for me, my apprenticeship has given me the opportunity to enter the next phase of my career feeling confident and accomplished with my achieved qualifications, and with a great deal of experience in the heritage science industry.

Learn more about apprenticeships and the different pathways into building conservation careers. Also read our excellent publication with resources about women in construction and start building your career.

About the author: Jasper Croser is in her third (and final) year of a Modern Apprenticeship. She is based within our Heritage Science Team, which applies conservation techniques to historic places and collections objects

About the author:

Guest

From time to time we have guest posts from partners, visitors and friends of the Engine Shed.

View all posts by Guest